Blue Water Molding is a full-service injection molding company. We offer Production, Service and Prototype runs of all sizes. For 17 years we’ve helped our clients turn vision into reality. Find out what we can do for you!

We offer injection molding of many materials. Nylon, Polypropylene, ABS and most high heat materials. Together with Blue Water Tooling, we can complete your tooling and molding from start to finish.

When high or low production volumes are required, Blue Water Molding has you covered. We specialize in consistent on-time deliveries, without sacrificing quality.

Need a short prototype or service run? We have that too. Ask us how we can get you scheduled.

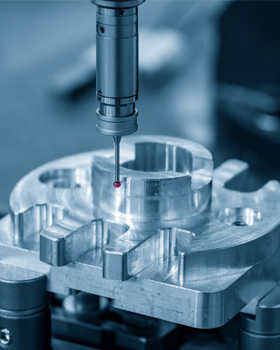

Collectively, the Blue Water Molding team has been providing exceptional injection molding, prototyping, and tooling services in the greater Detroit area for more than 15 years. Our design, CNC machining, EDM, tool making, and injection molding are all done in-house, allowing for greater efficiency and cost effectiveness compared to other molding and prototyping outfits.

Our in-house processes also grant us the flexibility to take on highly customized projects and provide agile customer service. For precision molding paired with unbeatable customer service, the best choice is Blue Water.

Blue Water also offers custom tooling designs, repair, and consultation. Visit our tooling site to learn more!

We carry ISO-9001 certification for the automotive and consumer industries, a testament to our lofty production standards and exceptional customer satisfaction.

Our injection molding services meet the needs of a wide range of industries, from automotive manufacturing to niche and specialty consumer goods. Contact us today to see how we can help you.